NEWS

Addressing backlogs in level crossing assessments

March 2024

Traditional methods for assessing level crossings involve sending personnel into the field to make observations manually. However, recent research undertaken by Agonics, in collaboration with the NTRO – National Transport Research Organisation, is setting the stage for substantial advancements in this space. In this article for Infrastructure Magazine, we delve into a new desktop-based process for assessing level crossings that are set to improve the way these critical safety evaluations are carried out.

We hope you enjoy the read.

Introducing Our Three-Step Process for Enhanced Rail Asset Information.

March 2024

We have devised a new three step process to improve asset information in rail asset databases. Interested in knowing more? Watch the video below

Project Spotlight: MLS Success on the Carmichael Rail Network with Bowen Rail.

February 2024

Recently, we completed a Mobile Laser Survey (MLS) across the Carmichael Rail Network on behalf of Bowen Rail Company. This project featured our new MLS system, which seamlessly integrates LiDAR with high resolution panoramic imagery of the rail corridor. Despite two cyclone events, the close collaboration between the teams ensured minimal impact to train operations and zero incidents.

Corridor datasets are made available to Bowen Rail via our cutting edge XERRA platform, Australia’s leading LiDAR and imagery visualisation platform for rail businesses, to support Bowen Rail’s maintenance and operations.

Are you interested in how our services can help in your next projects? Get in touch.

Enhancing Rail Construction: The Power of MLS for Dilapidation Surveys.

February 2024

Dilapidation Surveys are often just a footnote in rail construction contracts. Did you know that Mobile Laser Surveys or MLS are a great way to meet a contractual requirement in a quality assured way? In this short video, we explore the benefits of the approach.

If you are interested in knowing more about how to efficiently meet Dilapidation Survey obligations in construction, please get in touch at enquiry@agonics.com

Agonics Nominated for the Ken Erickson Innovation Awards .

January 2024

We are excited about being nominated again for the Ken Erickson Innovation Award category for our Line of Sight Assessment Digital Workflow. You can see a short video on the innovation here….

2023: A year of Milestones and Growth.

January 2024

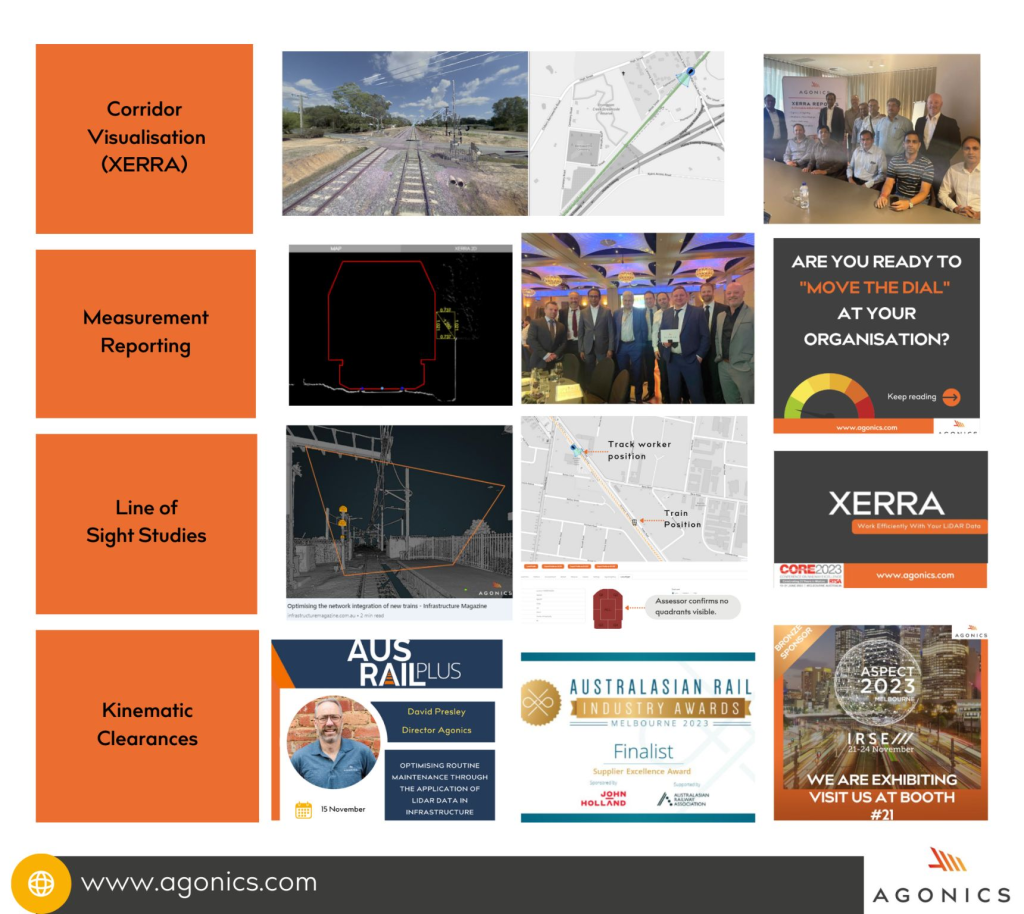

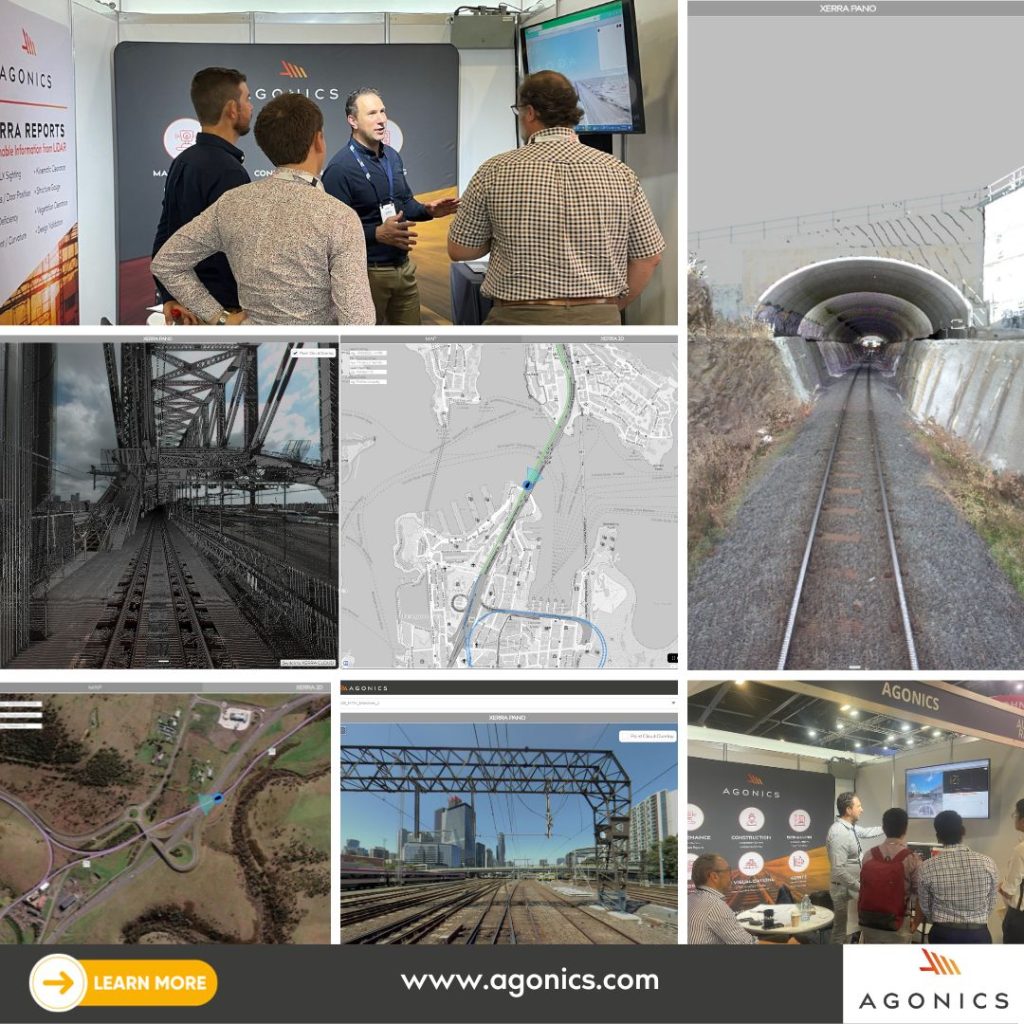

As we start a new year, we look back at the many great interactions we had in 2023 and we thank our clients for continuing to challenge us with projects that make the rail industry one of the most exciting spaces to work in.

Each image in this collage captures a significant moment, reflecting the milestones we have achieved and the great people we have met.

In 2024 we look forward to new challenges and to new projects as we continue our mission to be the most trusted supplier of LiDAR and imagery services, software and reports to the railway industry.

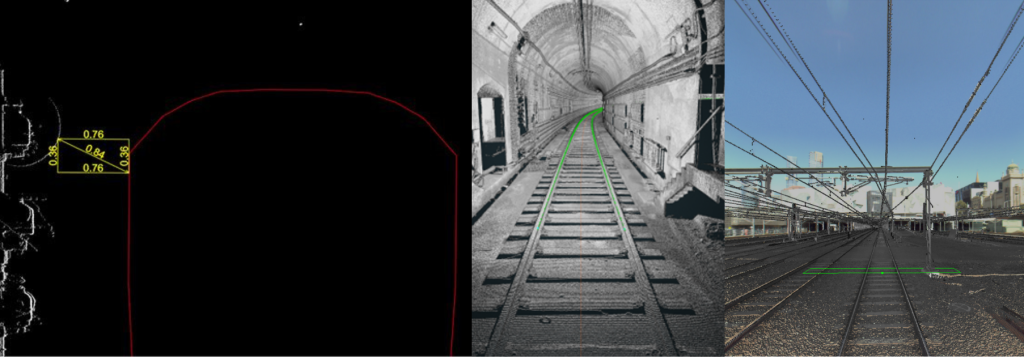

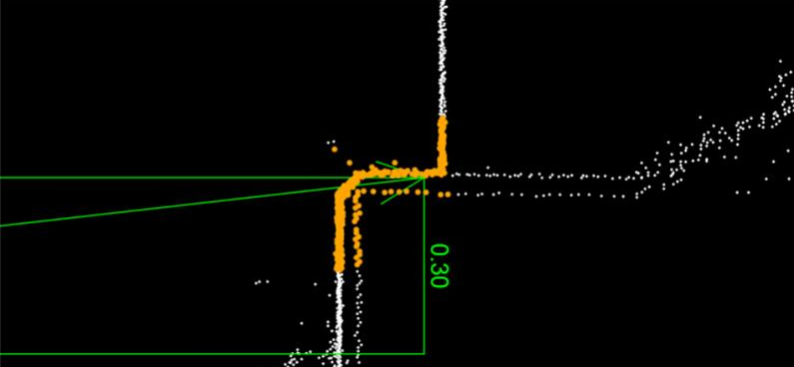

Introducing Line of Sight Assessments, the new track worker safety feature in XERRA.

LOS Assessments using LiDAR are a safer, more auditable way to ensure worker safety before setting up a worksite.

For more information, get in touch with us at enquiry@agonics.com

Agonics showcases XERRA’s advanced rail LiDAR processing capabilities at AusRail Plus 2023.

November 2023

AusRail Plus was a huge event this year and we’re delighted to share some snapshots from our booth. A heartfelt thanks to everyone who stopped by.

We very much enjoyed our interactions with you and we were thrilled to be able to showcase the latest advancements in our #XERRA platform, the leading #LiDAR and imagery visualisation and analytics software for rail users. Your questions and suggestions are truly important to us.

Interested in how #XERRA can optimise rail business processes?

Agonics announces Bronze Sponsorship of ASPECT 2023.

November 2023

We’re thrilled to announce our participation in ASPECT 2023, taking place this week in Melbourne. Our team is eager to demonstrate how our cutting-edge LiDAR-based solutions can significantly reduce risks in signalling projects. Following our successful showcase at the AusRail Plus conference last week, we are excited to present our XERRA platform to the ASPECT audience. Join us to explore how XERRA and our other advanced technologies are making a positive impact in the rail industry.

Towards safer level crossing assessments.

November 2023

Ensuring safety at railway level crossings remains a significant challenge on the Australian continent. According to the Office of the National Rail Safety Regulator (ONRSR) accidents at level crossings still make a significant contribution to the total number of railway-related fatalities that involve members of the public. With 23,000 level crossings in Australia and many in remote locations, assessing these crossings as safe for road transport users is resource intensive and costly to undertake.

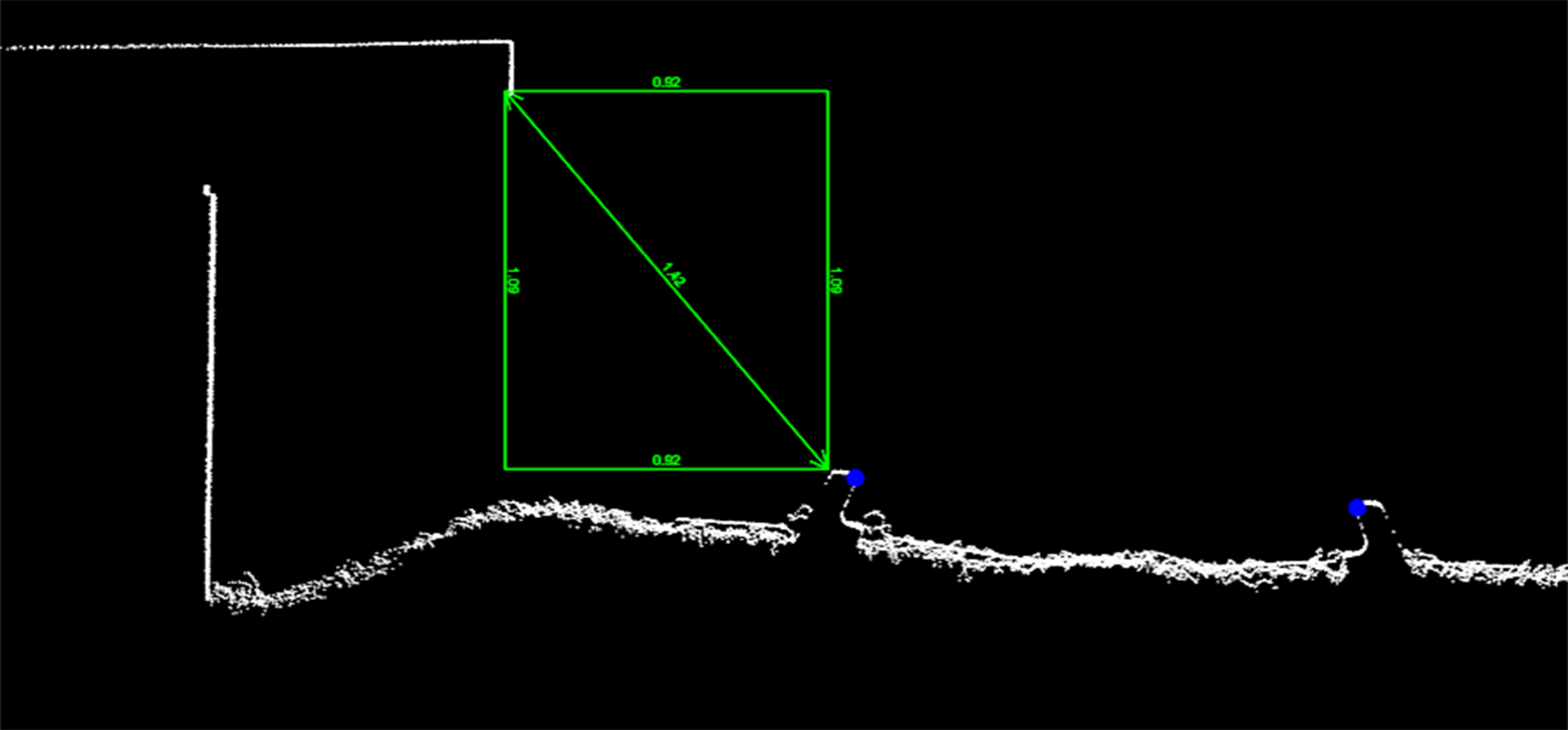

One of the key safety concerns at level crossings is maintaining adequate sighting distances. The sighting distance is the distance from which drivers can first see an approaching train, which is critical for their safety. Adequate sighting distances ensure that road users have early visibility of approaching trains and are essential in preventing collisions.

Agonics welcomes Dedicated Freight Corridor Corporation of India.

November 2023

This week we hosted a visit to our office by #DFCCIL, the Dedicated Freight Corridor Corporation of India, #Austrade and #Techwave. It was a very interactive session and it was fun showcasing our work and advanced technologies including our XERRA platform to a knowledgeable and engaged audience. It was also great to learn more about the Indian Railway industry. Thanks again to #austrade for making the connection. We look forward to future discussions and collaboration.

Agonics showcases XERRA at AusRailPlus 2023.

November 2023

#AusRailPlus 2023 is just around the corner and we’re excited to be part of this year’s event. Make your way to booth #539 where we’ll be showcasing our XERRA platform the industry’s most widely adopted #LiDAR and imagery visualisation software.

This year has seen important updates in XERRA, including new sighting distance calculations to signals, critical for integrating new train fleets. Team members Finbar Holland, Jamie Ibrahim, and Dave Presley are looking forward to answering your questions and showing how #XERRA is adding value to rail businesses.

Agonics and Sydney Trains to present on optimising routine maintenance with LiDAR datasets.

November 2023

Join us next week at #AusRail in the #PWI technical session where we will present a paper with Sydney Trains on how to optimise routine maintenance through the application of LiDAR Data. Further information on the topic can be found below:

The presentation is scheduled for Wednesday, November 15, 2023, at 3:45 pm.

Agonics releases XERRA: New Interface Enhancements for LiDAR Processing and Visualisation.

October 2023

In a significant update, Agonics has launched the latest version of XERRA, elevating the standards in LiDAR processing and visualisation. The refresh introduces a user-friendly interface, ensuring a smoother and more intuitive experience. A sneak peek video is now available, showcasing the sophisticated enhancements incorporated into XERRA.

➡ Want to see more?

Optimising the network integration of new trains.

September 2023

New train fleet purchases are considered to be one of the most strategically important investments that railway networks can make.

This is why, with many factors to consider, railway buyers should choose manufacturers that can deliver the right product for their network at a reasonable cost and within a reasonable timeframe, to successfully phase out aging fleets that are no longer fit for purpose for today’s public transport users.

Considerations such as total cost of ownership, ease of operation, and disability compliance must be expertly weighed up to land at the right investment decision.

With railway buyers faced with a small pool of potential manufacturers that offer standardised designs to meet a global marketplace, the integration of new train fleets into existing network infrastructure is expected to present challenges in terms of compatibility with signalling systems and at platforms where the transport user interfaces with the new fleet.

Compatibility issues that could arise include impacts on sighting distances to existing signalling assets that can occur when new cab designs leave the driver with a more restricted view than before….

Agonics Joins Industry Leaders at ARA Awards.

September 2023

The Agonics team and our invited guests had a fantastic night at the Australasian Railway Association (ARA) Awards. It was great to catch up with many familiar faces, surrounded by people who love working in rail as much as we do.

Thanks to Australasian Railway Association (ARA) for such a fantastic night.

Congratulations to all the finalists and award winners.

Here’s a snapshot from our memorable evening:

Agonics welcome a new team member.

August 2023

As part of our ongoing series to familiarise you with the faces behind Agonics, today we’re profiling our new team member Leonard Gouzin

Holding a pivotal role in our company, Leo’s expertise in LiDAR capture, processing, and analysis, as well as his recent tenure as an Elevation Specialist at Land Use Victoria, makes him an invaluable asset to our team. Curious about his passion for the rail industry and what drove him to Agonics, we asked Leo to share his insights. Here’s what he had to say:

Agonics Leverages RIEGL’s LiDAR for Comprehensive Network Mapping.

August 2023

In collaboration with RIEGL, we utilise VUX-1HA laser scanners for our mobile laser scanning projects across prominent railway networks such as ARTC, Metro Trains, V/Line, TasRail, and Sydney Trains. Thanks to RIEGL Australia for mentioning our work. Find more details in the linked article. #Agonics #railinnovation #LiDAR #railprojects

Safety First: Agonics Supports #RailSafetyWeek, Advocating for Enhanced Caution and Awareness.

August 2023

🚉 Today marks the commencement of the #RailSafetyWeek. At Agonics, we are stepping forward to express our full support for this crucial initiative, highlighting the importance of being cautious around trains.

These accidents impact workers, families, and communities.

➡ Want to learn more? Visit the TrackSAFE Foundation. And remember, being safe near tracks is important every day, not just this week.

Always be mindful, and prioritize safety first!

Agonics Quality System Recertified, Upholding Project Excellence.

August 2023

At Agonics, we put quality at the core of everything we do so that we can help you ”Move the Dial’‘. Our quality system was recently recertified, so thanks to our hardworking team for their efforts. If you are ready to “Move the Dial’’ then get in touch.

Agonics Supports Female Participation in Sport and Workplace through AUJFC Sponsorship.

July 2023

Agonics proudly announces its sponsorship of the Ashburton United Junior Football Club (AUJFC), as part of its commitment to boost female participation in both sports and professional environments.

We believe in the power of diversity and are actively seeking talented female engineers, surveyors, software developers, and project managers. If you’re a professional in these fields and are eager to make a meaningful impact in the rail industry, we invite you to connect with us.

Join our team and help shape the future of the rail industry. Reach out to us at jobs@agonics.com.

Agonics named as a finalist for the Australasian Rail Industry Awards.

July 2023

We are absolutely delighted to have been shortlisted as finalists for the “Supplier Excellence Award” category as part of the Australasian Rail Industry Awards.

Thanks to the hard work and dedication of the #Agonics team.

Stay tuned for further updates on the awards ceremony as we celebrate this remarkable achievement.

Agonics excited to Announce Bronze Sponsorship at Aspect 2023.

July 2023

We’re thrilled to announce our Bronze Sponsorship for Aspect 2023 🚄, the Institution of Railway Signal Engineers (IRSE) international technical conference. This landmark conference unites manufacturers, suppliers, and technical specialists, all fostering innovation and progress. We are very much looking forward to connecting with both domestic and international delegates attending #Aspect2023 #RailIndustry #Innovation #LiDAR #Agonics

Stay tuned for more updates from Agonics at Aspect 2023.

Agonics highlights the power of LiDAR at CORE 2023 in Melbourne.

June 2023

Agonics was part of the CORE 2023 Railway Engineering Exhibition in Melbourne, highlighting the capabilities of their XERRA platform in harnessing LiDAR datasets for rail engineering applications.

Dave Presley and Jamie Ibrahim, key team members from Agonics, engaged with delegates in insightful discussions, shared valuable tips and presented a captivating demo of the XERRA platform. This demo attracted significant attention due to its innovative use of LiDAR technology in the rail industry.

Agonics would like to extend its gratitude to the organisers of CORE 2023 and all the attendees who engaged with them at the event. For those interested in learning more about the potential of the XERRA platform and its capabilities with rail LiDAR, please don’t hesitate to get in touch.

Compliance reporting from digital twins.

June 2023

The rising prominence of digital twins in infrastructure asset management and maintenance is promising to revolutionise the way railway organisations approach the monitoring and upkeep of critical infrastructure.

While the fever around digital twins continues unabated, the challenges in adapting digital twin technology in day-to-day routine maintenance and inspections cannot be overestimated. With careful planning and focus, these challenges can be overcome.

The problems begin with the basic fact that a digital twin is just one representation of a railway network….

Designed for rail professionals, XERRA makes it easy to interact with and share LiDAR data recorded on rail networks.

June 2023

📍 Visit us at CORE 2023, June 20-21 in Melbourne.

With XERRA users can:

➡ Visit project sites with a full 3D view of the rail corridor

➡ Take measurements in a 2D profile anywhere along the track

➡ Export profiles to other software

➡ Load vehicle outlines…. and much more.

If you are working with LiDAR on a rail project you need to be using XERRA.

CORE 2023 is coming up in just under two weeks.

June 2023

We are excited about participating in this biennial event and showcasing our XERRA software. Stay tuned for more updates.

Railway engineering projects: the importance of asset information.

May 2023

With a growing user base among Australian rail networks and Tier 1 contractors, XERRA is meeting the need of engineering project teams for accurate, reliable information on the rail corridor and assets.

Agonics team members had a fantastic night last Tuesday at the Australasian Railway Association (ARA) Rail Industry networking dinner in Sydney.

May 2023

Represented by Finbar Holland and Jamie Ibrahim, Agonics had a fantastic night last Tuesday at the Australasian Railway Association (ARA) Rail Industry networking dinner in Sydney they had a good catch-up with some colleagues and friends including Dr Allen Tam.

Here are some photos from the night:

In this video, we’ll share some practical tips and best practices for taking your asset inventory to the next level.

May 2023

Looking for a better way to visualize and interact with your LiDAR datasets?

April 2023

Make the switch to XERRA.

Learn more about our XERRA platform and book a demo here

Agonics welcome a new team member.

April 2023

Exciting news! #Agonics has a new team member! Please welcome Jamie Ibrahim as our new client solutions engineer.

Jamie brings a wealth of experience and expertise to our team, and we couldn’t be happier to have him on board.

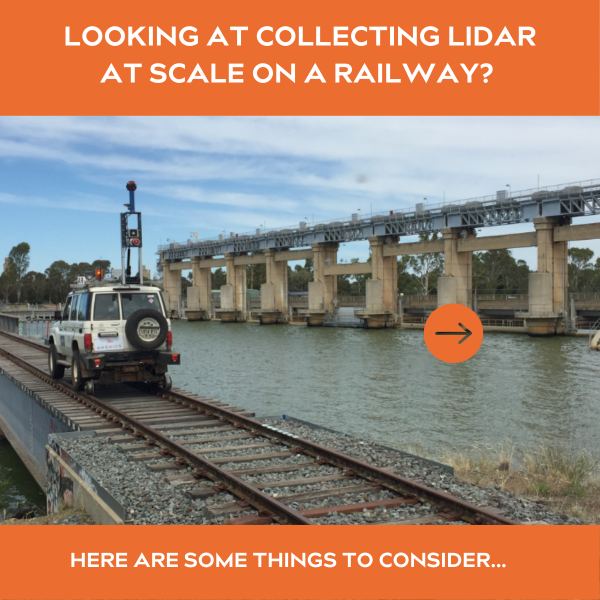

Looking at collecting LiDAR at scale on a Railway.

March 2023

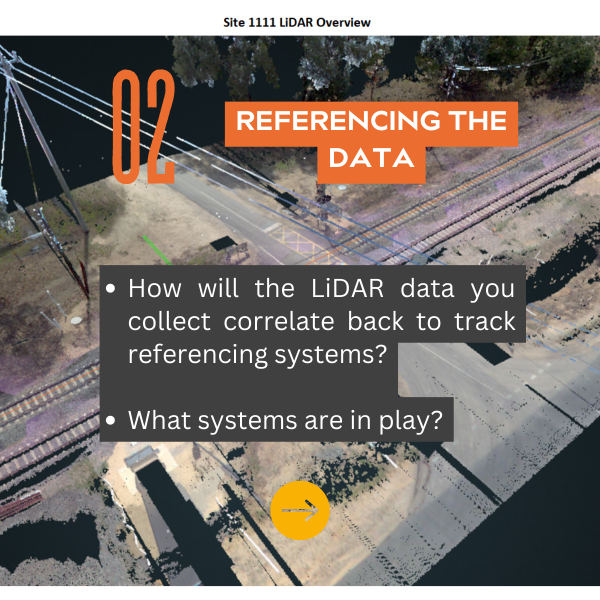

Here are some things to consider:

Exploring the Potential of LiDAR.

March 2023

LiDAR is a valuable tool and has many applications beyond the original project brief.

Here are some uses we put it to

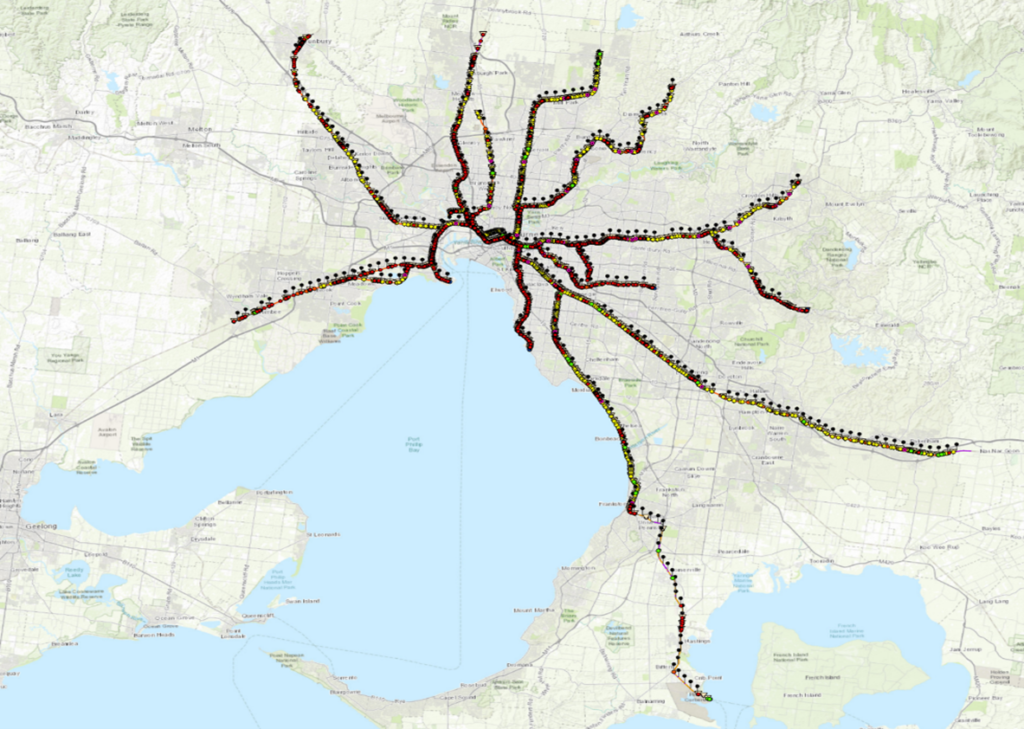

Agonics assists Metro Trains with a new digital track centreline to support the operation of their new track measurement technologies.

February 2023

Commissioning a new track condition monitoring vehicles are a once-in-a-generation purchase by railway operators. Recently we assisted Metro Trains with a new digital track centreline to support the operation of their new track measurement technologies. Mobile Laser Surveys (MLS), when executed correctly, provide valuable datasets for downstream projects. We’ve already digitised over 16,000 km of domestic network allowing refreshes to asset inventories, automation of measurement report, and enabling new digital systems.

Contact us today to learn how we can help you streamline your infrastructure projects.

Sydney Trains MIDT Project Wins Prestigious Innovation Award.

February 2023

At the NSW Permanent Way Institution awards held on Friday February 10, Sydney Trains was awarded the Ken Erickson Award for Innovation for its Measurement and Inspection Digital Twin (MIDT) project. The MIDT project aims to replace in-situ measurements of railway infrastructure with measurements taken from point cloud datasets. The award was given to a Proof of Concept (POC) project that tested LiDAR based measurements against nine routine inspection use cases resulting in all nine use cases being proved. Agonics was pleased to be selected as the sole partner to engage with Sydney Trains subject matter experts (SMEs) to work collaboratively to prove all nine uses cases, bringing our extensive experience, proven workflows and expert software to bear on this critical business initiative.

View our project below.

Agonics experts accelerate the adoption of LiDAR in routine maintenance on the Sydney Trains network.

Agonics appointed LiDAR acquisition partner for the Sydney Trains Measurement and Inspection Digital Twin (MIDT) project.

January 2023

This comes on the back of successful network-scale LiDAR acquisition projects undertaken for ARTC, V/Line and Metro Trains Melbourne. We are very much looking forward to working with Sydney Trains on this ground-breaking initiative.

If you’re looking to collect LiDAR and panoramic imagery on your rail network, whether that is for infrastructure compliance or as a dilapidation survey, don’t hesitate to get in touch with our experts by following the button below.

Agonics launches a re-designed website.

January 2023

Excited to launch our re-designed website; with a modern look and simplified navigation, our website puts the user experience first – so we can connect you to the information that you need. Visit our new projects page and learn more about our work and experience.

We’re proud of the final result.

Agonics participates in Ausrail Exhibition 2022 in Brisbane.

November 2022

We’ve fielded a lot of enquiries at AusRail, and it’s been great to connect with clients and friends in Brisbane. We help many different rail clients get actionable information from LiDAR datasets. If you want to talk to our experts, contact us now: enquiry@agonics.com

Digital Data in Track, Infrastructure and Rollingstock Compliance, A Perspective.

November 2022

Article created by Finbar Holland / Agonics

For new rollingstock and train control projects, as well as for routine infrastructure maintenance, accurate digital data can support a shift away from manual compliance methods towards an automated, fully auditable approach.

This year, Agonics has demonstrated to a major Australian railway operator that datasets recorded at scale could be processed to produce standardised measurement reports on rail track and infrastructure across a number of different asset classes. The project formed the basis for a business case approval to move from manual inspections to automated, LiDAR based reports, thus setting the scene for safer and more cost-effective inspections.

Agonics has been at the forefront in Australia in the digitisation of rail networks and our team has digitised over 16,000 km of domestic network to date. The downstream uses of this data are manifold and have included refreshes to network asset inventories, the automation of measurement reports on track and infrastructure, kinematic clearance analyses and nose cone design support for new rollingstock, level crossing sighting distance investigations, and dilapidation surveys for pre-construction works; the list is only growing as traditional work methods come under increasing scrutiny for their cost and resource intensiveness.

It is our view that changes in work practises in rail are accelerating as the industry increases its reliance on digital datasets that accuracy describe the network in its current state.

Powerline Clearance Assessments.

October 2022

The team has been working hard on our recent project with McConnell Dowell assisting in planning an important track capacity upgrade.

The project involved an audit of the powerlines that crossed the rail corridor between Craigieburn and Wodonga – a distance of approximately 280km.

De-risking the commissioning of new track monitoring vehicles.

Article created by Finbar Holland Agonics

September 2022

New track condition monitoring vehicles are a once-in-a-generation purchase by railway operators. Their onboarding typically involves the operation of complex instrumentation and track measurement technologies that are far more advanced than the organisation’s preceding vehicle capabilities.

The testing and commissioning of such vehicles can present a range of challenges to railways in terms of correlating data from these vehicles against legacy system measurements.

Typically, new condition monitoring technologies involve measurement systems from different suppliers and often include track geometry, rail profile, overhead wire and rail wear measurement systems.

While these suppliers are all experts at what they do, the data collected by these systems needs to be reconciled to a common track centreline so that observations, faults and trends can be assessed relative to the correct track code, track class and precise network location.

To test system accuracy and repeatability a common track centreline is, therefore, required. This needs to be spatially and topologically true, up-to-date with respect to track infrastructure, and delivered in a compatible way to the vehicle’s proprietary schema.

The challenge for the railway operator is in acquiring this digital track centreline in a way that facilitates timely vehicle testing and commissioning.

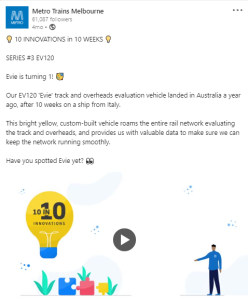

With a new track condition monitoring vehicle enroute from the US, Metro Trains Melbourne (MTM) needed to quickly acquire a digital track centreline to support the commissioning of the new measurement systems.

Generating this track centreline database, encompassing all MTM mainline track, required expert level spatial and rail asset domain knowledge.

Australian rail mapping business, Agonics, was engaged to first capture raw GPS and inertial position data across the network and then process this data using survey systems, advanced GIS and FME software into a unique track database format, mandated by the location software onboard the new MTM vehicle, called the EV120.

The digital track centreline, generated by Agonics, used recording and processing innovations to ensure that all high order features on the network such as turnouts, signals, kilometreage posts and kilometreage inequalities were reflected in the database.

A key innovation developed by Agonics throughout the project was the extension of its XERRA LiDAR solution to enable feature extraction and survey control validation.

Whereas track geometry vehicles can sometimes take many months or even years to deploy and commission, the new MTM EV120 critical measurement systems were tested and commissioned within a relatively short four month period.

Agonics attends ARA Awards Gala dinner.

September 2022

We had a fantastic night at the Australasian Railway Association (ARA) Awards Gala dinner. It was wonderful to catch up with so many familiar faces, surrounded by people who love working in rail as much as we do.

Agonics has been shortlisted as finalist for the “Supplier Excellence Award” category as part of the Australasian Rail Industry Awards.

August 2022

Awards news!!

We are absolutely delighted to have been shortlisted as #finalists for the “Supplier Excellence Award” category as part of the Australasian Rail Industry Awards.

Thanks to the hard work and dedication of the #Agonics team.

Fingers crossed for the final!

Agonics is proud to have been selected as the tracks database supplier for the new EV120.

August 2022

Congratulations to Metro Trains Melbourne on the successful commissioning of Evie!! Agonics is proud to have been selected as the tracks database supplier for the new EV120.

After final farewells to the EM100/IEV100 this is an exciting new era for Victoria’s track geometry and condition reporting professionals.

Agonics becomes a member of the Australasian Railway Association (ARA).

July 2022

Exciting News… !!

Learn more: https://www.linkedin.com/company/agonics/

Parallels between GPS and LiDAR adoption by industry.

June 2022

Article created by David Presley Agonics

As LiDAR becomes more important in day to day rail operations and maintenance we asked Agonics Director, David Presley, about the parallels between the historical adoption of GPS and the current adoption of LiDAR by industry.

This is what he had to say:

“I’d say that just as LiDAR is gradually becoming accepted by rail for use case and compliance reporting, the adoption of new GPS technology by the offshore oil and gas exploration sector last century was similarly cautious and, in some quarters, treated with scepticism”

“In the early 90’s (for the information of my colleagues at Agonics I am of course referring to the 1990’s), I worked offshore in the oil and gas sector and for many years rig and pipeline vessel navigation was required to be supported by both radio (transponder) positioning and GPS positioning. It took several years for that industry to have confidence in the reliability and accuracy of GPS before it was accepted as the sole and primary positioning system. We see the same cautious approach to LiDAR technology today; system calibration, control point validation within a LiDAR point cloud and manual vs LiDAR repeatability checks are necessary for the rigour of our work but also to demonstrate that the new technology can go toe to toe with traditional manual measurements”

“I’d say that just as the raw GPS signal was, over time, able to be post-processed to achieve much higher levels of accuracy than could ever be achieved with a long rage radio transponder system, the LiDAR technology today with machine-learning feature recognition capabilities is able to take more measurements, with greater accuracy and certainty that manual measurements. Not necessarily in all cases mind you, but nevertheless across many on-track applications that were until 10 or so years ago only done by manual means, today the application of LiDAR data by railroads is becoming pervasive.”

Lucy Davis, team member and spatial engineering undergraduate RMIT.

May 2022

In order to introduce you to some of our team, we are profiling team member, Lucy Davis. We asked Lucy why she chose to work in the rail industry while studying for a degree in surveying at RMIT. This is what she had to say:

“I didn’t know much about the rail industry before I started working for Agonics and so in a way, it is something that I have fallen into. I joined Agonics because they were looking for people to work on some large mapping projects and they have a strong reputation for excellence in spatial engineering.

“I didn’t know much about the rail industry before I started working for Agonics and so in a way, it is something that I have fallen into. I joined Agonics because they were looking for people to work on some large mapping projects and they have a strong reputation for excellence in spatial engineering.

For my final year dissertation, I will pick a subject matter that relates to my work at Agonics. I feel that I am in a unique position to share some really good learnings with the student body”.

Lucy’s recent projects:

- Lucy’s recent projects:

- Metro Trains Melbourne (MTM) Whole of Network LiDAR Survey

- V/Line Whole of Network LiDAR Survey

- Department of Transport (VIC) Bridges Study

- SEPA Level Crossing Removal Project – EACR preparation.

TasRail Undertakes Network Wide MLS Project.

May 2022

Our team has recently completed an MLS recording campaign across the TasRail network following on from a previous campaign carried out some years ago. The MLS project will give TasRail up to date imagery and LiDAR datasets across approximately 630 km of the freight network. Agonics will also be undertaking downstream processing and analysis of the datasets to deliver encroachment and vegetation clearance studies using its XERRA software, the leading LiDAR processing and analysis platform for rail engineering applications.

XERRA Cloud automates Road over Rail Bridges Investigation.

February 2022

As an approved supplier of geospatial asset information to the Victorian Department of Transport, Agonics has been engaged to prepare an authoritative database of road-over-rail bridges. To do this project Agonics will leverage its extensive MLS (Mobile Laser Scanning) library across the Victorian rail network as well as its in house XERRA LiDAR cloud solution to automate the investigation as much as possible including validations against existing asset management systems. More than 300 unique bridge assets will have been identified by project completion.

Data processing by Agonics has allowed Coleman Rail and its track consultants to calculate the track modulus at each site; this information will be used to assess the extent of work required and associated costs to lift sections of the Victorian rural rail network to a higher track class.

Two pilots studies of the Agonics deflection solution were completed at Williamstown and Wyndham Vale stabling yard utilising a range of track vehicles and under day/night conditions before embarking on the mainline scope. Once mobilised, the team negotiated a wide range of site conditions while navigating the frequent changes to COVID19 working restrictions during Victoria’s current outbreak.

Rail Deflection Tests Using Photogrammetric Methods.

November 2021

Longstanding clients Coleman Rail and parent company, Acciona, approached our team with a track deflection challenge that required very accurate measurement of the rail displacement as a locomotive was driven through a project site.

The project site encompassed more than 100km of regional track and more than 200 deflection sites were nominated by the client in concert with a parallel geotechnical investigation. Agonics worked closely with partner, Gancel, and the Geodetic Systems International (GSI) industrial photogrammetric technology to design a rail deflection process that would capture deflections at both sleeper and mid-crib locations.

Data processing by Agonics has allowed Coleman Rail and its track consultants to calculate the track modulus at each site; this information will be used to assess the extent of work required and associated costs to lift sections of the Victorian rural rail network to a higher track class.

Two pilots studies of the Agonics deflection solution were completed at Williamstown and Wyndham Vale stabling yard utilising a range of track vehicles and under day/night conditions before embarking on the mainline scope. Once mobilised, the team negotiated a wide range of site conditions while navigating the frequent changes to COVID19 working restrictions during Victoria’s current outbreak.

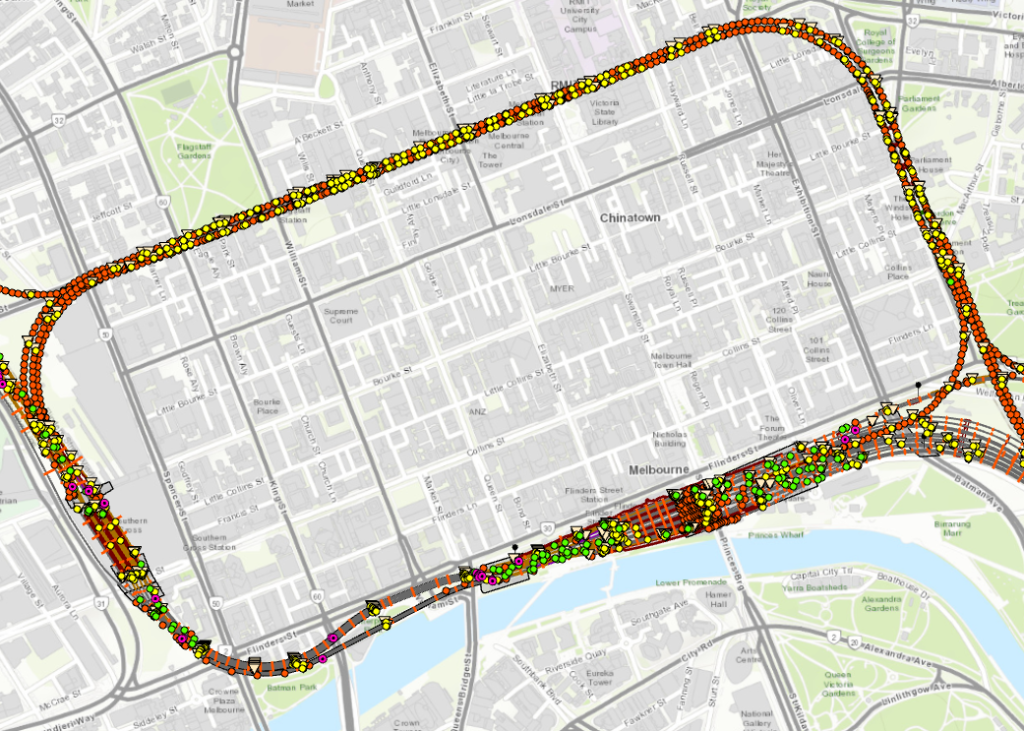

Metro Trains Melbourne (MTM) Embarks on Whole of Network MLS Project.

November 2021

In preparation for the commissioning of a new track inspection vehicle and to realise an update to the Melbourne rail network asset inventory, MTM has partnered with Agonics to perform a whole of network MLS survey. The survey commenced in September 2020 during Melbourne’s strict midyear lockdown with the project teams implementing comprehensive COVID safe protocols. Since then we have completed recording across 880 km of complex inner city and suburban rail network and have processed what are arguably the most accurate LiDAR and imagery datasets ever recorded on the network.

Similar to our other rail network clients, the LiDAR and imagery datasets are being made available to MTM through the easy-to-use AIMS3D Viewer supporting internal projects and day to day maintenance and operations. The datasets being delivered will also play a critical role in the commissioning of a new track recording vehicle that is currently undergoing testing in Melbourne.

The new vehicle will avail of digital track centrelines produced by the MLS project so that geometry and other infrastructure defects can be accurately and repeatedly referenced in MTM’s maintenance systems. To ensure compatibility between data and systems and, most importantly measurement reporting repeatability, the track centrelines delivered by Agonics have been translated by us into the ENSCO track database that feeds localisation content to the various systems and reports generated by the IEV120. Establishing this new, authoritative track centreline database inclusive of speed limits, crossovers and turnout topology to an absolute accuracy of 100mm has ensured the smooth commissioning of the new vehicle.

Agonics Insight – Getting Actionable Information from LiDAR Data.

October 2021

There is little doubt that LiDAR is playing an increasingly important role in day-to-day rail maintenance and planning. In Australia we see a strong desire amongst our rail clients to leverage LiDAR more in their business, but LiDAR datasets alone are only part of the story. We asked Agonics Technical Director, David Presley, what networks should look for in terms of integrating LiDAR into their routine maintenance practices.

“I would say that from decades working with rail clients the same basic principles apply to solving any engineering challenge. The first of these is to understand what your actual requirements are before commissioning any LiDAR survey or buying hardware to do it yourself. A common pitfall is to focus on the hardware at the expense of downstream thinking as LiDAR scanners are relatively easy to understand and compare. However, the ancillary technology such as inertial measurement devices and trajectory understanding, which are needed to inform the raw LiDAR data and allow correlation back to the track reference systems, are often not on people’s radar. We’ve seen so many examples of datasets being collected without first really understanding why or without mapping out a workflow that will take this data and solve a business problem with it.”

“The second principle I think is to not underestimate the change management needed in your organisation to leverage LiDAR successfully in day-to-day maintenance. We are beginning to see some real maturity in this space now in the industry, which is great to see.”

Amazing Structures being mapped by our team.

July 2021

We’ve been very busy of late helping our rail customers manage engineering compliance for their infrastructure assets. Occasionally we get to witness some of the amazing work of our forebears. Here are a few photos of some beautiful engineering structures in Victoria. If you need assistance with meeting PASS Assets requirements, please contact our expert team.

Agonics and ARTC complete Australia’s Longest Digital Twin.

May 2021

We recently completed data collection for Australia’s longest digital twin – 9,000 km of the interstate Freight network on behalf of ARTC. This has been a mammoth task requiring close collaboration among the project stakeholders. The datasets collected will go to meet the immediate and evolving requirements of ARTC projects and support the development of an ARTC GIS Model, Linear Referencing System as well as the deployment of Ellipse Mobility eWorks. To read more on the project please read this article Infrastructure Magazine: ARTC creates digital twin of entire network | Infrastructure Magazine

Artificial Intelligence (AI) and Machine Learning.

We often get asked if we utilise AI and/or Machine Learning when we analyse LiDAR and imagery. The short answer is, yes, we do, but we advise our clients to always exercise their engineering judgement in deciding what level of automation is suitable in their particular circumstances. The rail environment is complex and so, if you are interested in learning more about how we analyse imagery and LiDAR then please get in touch with us at enquiry@agonics.com